For a PDF study plan download, click HERE

We invite you to compare the accommodations of our TEMPEST design with those of boats much larger. For example, virtually half the boat is devoted to outdoor activities yet the cabin is truly spacious. There's a private owner's stateroom aft with hanging locker, fully enclosed toilet room with shower, an inside dinette-convertible berth that supplements the outdoor dining lounge, a complete galley opposite, and another double berth forward that can be curtained off for privacy. Storage and shelf spaces abound, yet the cabin has an open, airy, appearance.

Moving aft and topside on the TEMPEST brings you to what's best described as the outdoor living area. Here's an outdoor dining lounge that also converts to a double berth for sleeping under the stars. There's space for a bar that can be fitted out with an ice maker or refrigerator. The cockpit is large and deep (32" min.) and self-draining making it suitable for fishing, diving, or lounging about. The control station is situated so the helmsman can join in on all the fun, yet still offers full circle visibility. In fact, this is a boat that's even practical for water skiing if the urge strikes.

TEMPEST can really perform, too. The hull is a full length 18o minimum deep vee with stabilizing, spray-deflecting lift strakes and a ride softening bulbous keel section. Hull depth is comparable to much larger boats for security. The attractive topsides flare outward in broad reverse curves. This shape results in ample reserve bouyancy forward that prevents plunging in headseas and helps keep spray off the deck.

Building your own TEMPEST is not as difficult as you might think. Since our designers are amateur boatbuilding specialists, the methods and materials have been adapted to the abilities of the do-it-yourselfer whether choosing to build in wood or fiberglass. WOOD versions are cold-mold planked using strips of plywood or solid wood veneers, applied diagonally in layers over sawn frame members, reinforced by longitudinal battens inside. No difficult woodworking operations, such as steam bending are required.

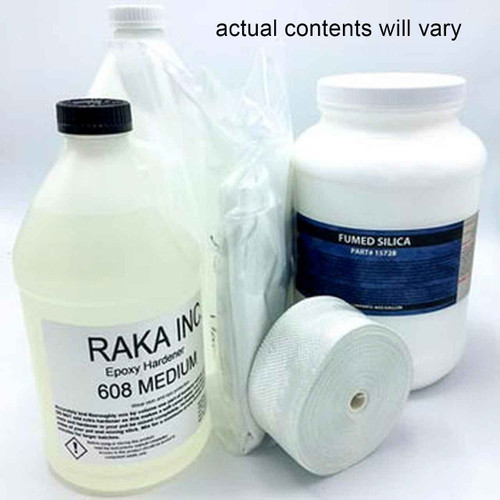

For FIBERGLASS hulls, the proven one-off male mold methods are used, either fiberglass planking (C-FLEX) or PVC foam sandwich. Either method uses internal reinforcing longitudinal and transverse members for a strong but lightweight hull. Cabin construction in all versions uses simple wood and plywood materials, with exterior surfaces sheathed in fiberglass.

- Length overall:

- 27'-0"

- Length waterline:

- 22'-8"

- Beam:

- 9'-11"

- Hull draft:

- 16"

- Displacement:

- 6800 lbs.

- Hull weight (approx.):

- 2000 lbs.

- Hull depth:

- 6'-2"

- Freeboard forward:

- 4'-10"

- Freeboard aft:

- 4'-6"

- Headroom:

- 6'-3"

- Height overall:

- 9'-8"

- Cockpit size:

- 9'-0" x 6'-0"

- Fuel capacity:

- 115 gals.

- Fresh water capacity:

- 40 gals.

- Sleeping accommodations:

- 5-7

- Hull type:

- Full planing hard chine. Bottom has full length deep vee with 18o minimum deadrise, bulbous keel section, and lift strakes. Sides have reverse curve flaring sections forward and canted raised topsides above sheerline.

- Construction:

- Wood hulls are triple diagonal planked to 3/4" on bottom; sides are double diagonal planked to 1/2". Fiberglass hulls are built using "one-off" male mold methods, either fiberglass planking or PVC foam sandwich construction.

- Power:

- Single or twin stern mounted engines driving through outdrives or vee drives. Engine weight range: I/0 - 750 to 1600 lbs. V-drive: 850 to 2000 lbs. Other stern mounted drive systems optional but not shown on plans.

- Can the hull be extended or shortened?:

- Yes. Up to 10% by re-spacing the frames from the aft end of the stem to the transom a proportional amount. We do not recommend increasing the beam.